Anatomy of a Sharp Knife Edge

The most important thing that affects how a knife performs is the blade. And the thing that determines the utility of the blade is a curved section near the blade’s sharp cutting edge known as the bevel. A knife generally has two bevels on both sides of the blade. As they curve forward and meet at the end, they form the blade’s thinnest and sharpest point, the cutting edge.

Creating the perfect bevel takes years of experience to perfect, from the knowledge to set up the sharpening machine to the right settings to the right pressure and whether to pull or push with greater force. But it all starts at choosing the right grinding profile, and that is where the first differences between FoodPrep Solutions sharpening and retail sharpening differ.

Hollow Grinding for the Ideal Bevel

Most knives you buy in a store won’t look like ones from FoodPrep Solutions, and there’s a reason for that. Retail knives are often fabricated with machinery and shipped to the store without having a thin bevel ground onto the knife. Your knife might be sharp when you first use it but that will quickly give way to struggling with a thick edge that needs professional maintenance.

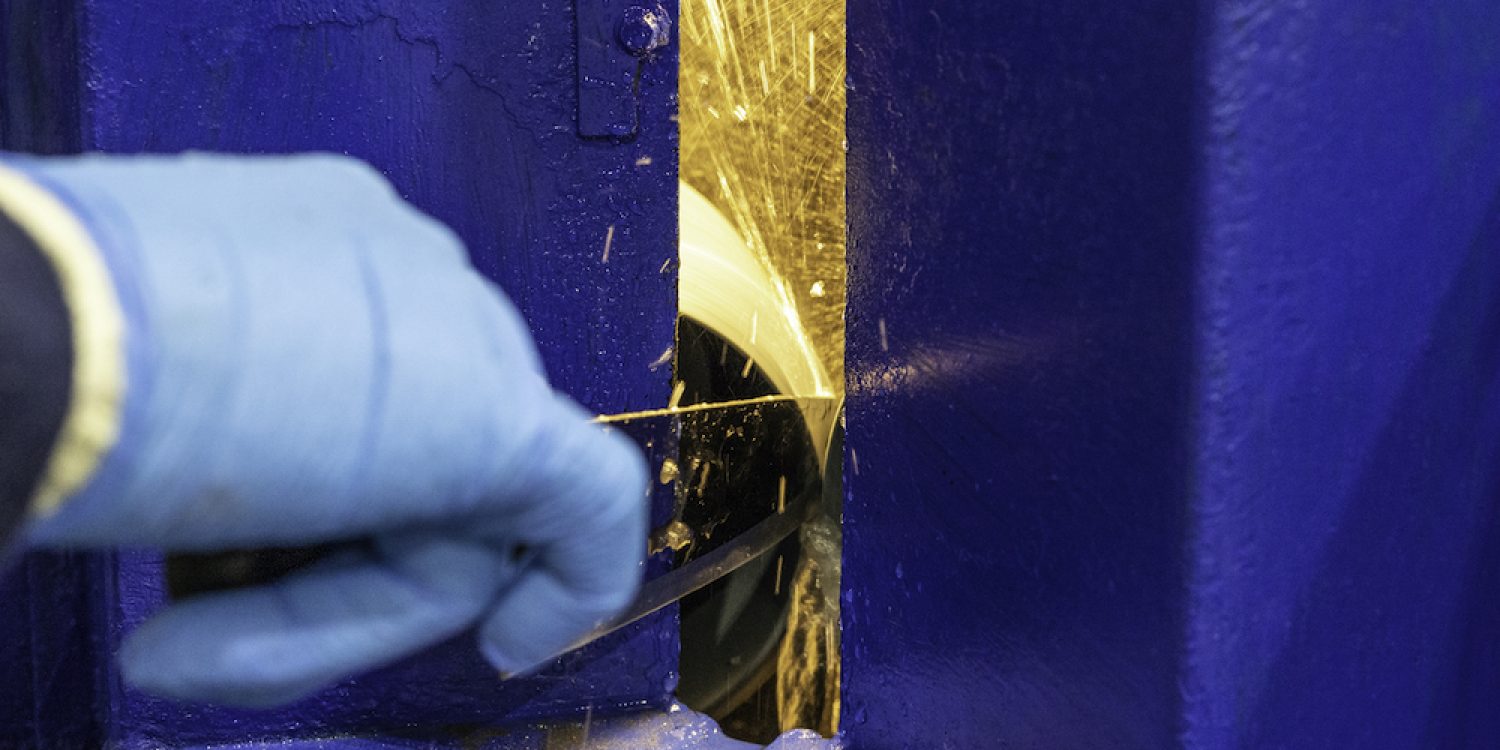

Knives from FoodPrep Solutions are hand-ground in our sharpening shop to very precise specifications. Our hollow grinding process produces a thin bevel that allows our knives to slice effortlessly through even the toughest kitchen prep. It’s a bevel that only an experienced sharpener can create.

The hollow grind produces a concave edge, meaning it curves inward. We use a grinding wheel to shape blades with a hollow grind, resulting in a thick spine able to resist significant shock and a thin edge with a razor-sharp blade. It’s an ideal cutting blade for a busy commercial kitchen, deli, or butcher shop.

Honing and Polishing to Perfection

After our bevel creates a thin edge to work with, we fine tune our edge in a process called honing. You can think of this in the same sense of what waxing is to washing your car. Sure, the car wash does a great job, but it’s not complete without the finishing touches.

Our hones are preset to a 35 degree angle. You’ll often read of steeper angles on many knives, but over the decades we’ve come to find that knives function best at 35 degrees and don’t chip as easily. Plus, with a beveled edge, you’ll be working with less drag. After honing, a nice polishing finishes off the process, all adding up to a sharp knife that you’ll be happy to prep with every time you use it.

The Sharpening Winner

Most retail stores pass your knife through a one-size-fits-all sharpener. This is almost guaranteed to take off more metal from your knife than necessary, which will shorten its lifespan and alter the silhouette. Also, it’s more likely for a retail store to overheat the blade, destroying the metal’s temper and making it brittle and vulnerable to breaking.

And we can’t reiterate enough how much talent and practice is involved with proper knife sharpening. It can take years to master the skill. A professional knife sharpening service means that your knives are in top shape every time you go to use them. Professional sharpeners correct things that are easy to miss with with the naked eye – like small waves and chips in the blade – that a retail store is not prepared to handle and fix.

Commercial kitchens need properly sharpened knives for a multitude of reasons. And partnering with a professional sharpening service like FoodPrep Solutions who not only keeps your knife blades sharp, but can also answer your questions and catch minor issues before they turn into big problems, is a major asset to your business.